50th MPA Conference

October 5th – 7th 2026

Stuttgart, Germany

The last conference was a huge success with amazing speakers, engaging sessions and great guests. We would like to thank our program committee and all the helping hands.

Next year will be special: After its debut in 1975, we will be hosting the 50th edition of MPAC in 2026.

MATERIALS

PROCESSES

APPLICATIONS

MPA Conference 2026

Materials Testing Institute (MPA)

Our Sessions. each one whole day long

The intricate interaction between materials, processes, and applications is the backbone of innovation and performance optimization. Materials must be carefully selected and designed to meet the specific demands of various applications, considering factors like strength, durability, and thermal resistance. In contrast to their continuum mechanical models, real materials have a real microstructure with imperfections, anisotropy, segregations, discontinuities, pores and residual stresses.

The intricate interaction between materials, processes, and applications is the backbone of innovation and performance optimization. Materials must be carefully selected and designed to meet the specific demands of various applications, considering factors like strength, durability, and thermal resistance. In contrast to their continuum mechanical models, real materials have a real microstructure with imperfections, anisotropy, segregations, discontinuities, pores and residual stresses.

These result from the respective manufacturing process of the material or component and have a significant influence on the material behavior and structural integrity in safety-critical applications.

These result from the respective manufacturing process of the material or component and have a significant influence on the material behavior and structural integrity in safety-critical applications.

This dynamic relationship among materials, processes, and applications is a key focal point in advancing several sub-fields in mechanical engineering, with each element influencing the overall success of mechanical engineering endeavors.

Key Dates & Deadlines

Program Committee

Our scientific committee is composed of recognized experts from academia and industry. It is led by

our hosts Prof. Stefan Weihe and Dr. Martin Werz.

Andreas Fezer

MPA Uni Stuttgart

Dr. Anne Jüngert

Kernkraftwerk Leibstadt AG

Pricing

Speakers get a 200€ Discount

1 Day

2 Days

The Whole Conference (3 Days)

Early Bird - 1 Day

Early Bird - 2 Days

Early Bird - The Whole Conference (3 Days)

Why Attend?

Join us at the MPA Conference 2026 to connect, learn, and contribute to the future of materials science.

Our Conference was first held in 1975 and has its roots in power plant technology. Over the years our conference evolved and now covers a wide range of topics, that are very relevant for the global challenges of today and tomorrow. While driving innovation, bridging gaps and accellerating progress by bringing experts together. Make sure to register to be a part of this exciting event. Early bird registration is possible between April 13th and June 26th.

Sponsoring and Exhibitors

Partner with us as a sponsor to get exclusive brand exposure and establish strong relationships in the scientific community, all while building a brand profile where it matters. The possibilities are endless. You could, for example, present your products, host an event or sponsor an award. Interested? Become a part of MPA Conference now!

Please contact Dr. Martin Werz for sponsoring or exhibition requests.

a GREAT SEMINAR LIES BEHIND US!

This was the 49th MPA Seminar 2025 is over. Let us remember some Special moments.

Questions?

Send a mail to the team

Materials for future applications

At the core of the MPA conferences attention lies the pivotal role of materials, where they confront a host of complex challenges. While steel in various forms as austenitic or martensitic continues to play a crucial role, evolving applications necessitate the use of other materials like nickel-based alloys, titanium and high-strength aluminum.

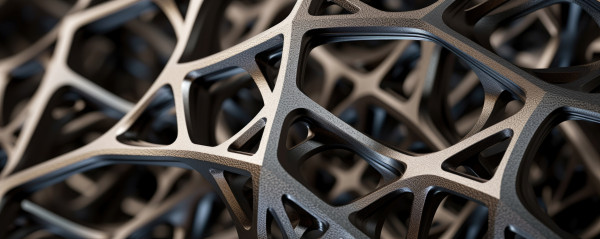

Moreover, the introduction of innovative manufacturing processes enables the design and manufacturing of more complex structures and components and the utilization of a broader spectrum of materials. Nevertheless, the surging costs associated with increasingly precious alloying elements present formidable obstacles. Further challenges include but are not limited to highly flexible load cycles, material behaviour under harsh environments like extremely high and low temperatures as the bevhaviour under the influence of media, especially biogas and hydrogen. The performance of materials dominates the performance of the end product, emphasizing the need for efficient resource utilization in their application.

Processes that amplify industries

At the MPA seminar, processes are not only understood as manufacturing processes in the classic sense. Instead, complex load cases are also regarded as processes resulting from the application and having a decisive influence on the structural integrity and life time of components.

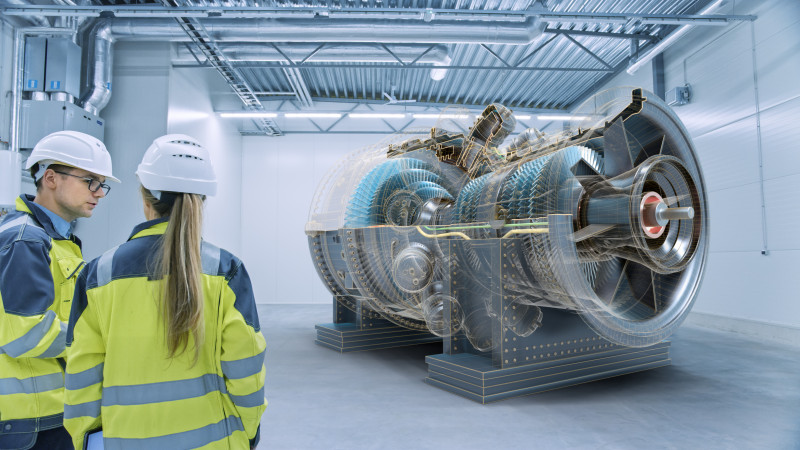

We will take a deeper look into a range of state-of-the-art manufacturing processes, including additive manufacturing processes such as laser powder bed fusion, wire arc additive manufacturing, direct energy deposition, additive friction stir welding, and electron beam melting. Other manufacturing processes include electron beam welding, hot isostatic pressing and cold gas spraying. Understanding not only potentials and advantages but also limitations of these manufacturing processes and how they shape the real microstructure of the processed materials including segregations, anisotropy, flaws, pores etc. is of crucial importance. Together with high and complex stresses in application processes, including factors like creep, cyclic fatigue, impact load, and thermomechanical effects micro- and macrostructure resulting from manufacturing processes determine the structural integrity and life time of components.

Applications for future materials and processes

Applications in materials and mechanical engineering vary widely, each demanding specific attributes from materials and (manufacturing) processes. These requirements include specific strength, creep resistance, and the ability to perform in high and low-temperature environments.

Whether it is energy generation with lots of pressurized components, turbine blades, and aerospace components or transportation systems, the materials used need to ensure failure safety and withstand high stresses and/or a high number of load cycles even in extreme conditions like hydrogen atmospheres. As new manufacturing processes and CAD design techniques lead to increasingly complex structures with elements like geometric compactness and function integration, the adaptability of materials becomes paramount in ensuring their suitability for diverse applications. The conference will delve into these crucial aspects, shedding light on the nexus of materials, processes, and applications in the realm of materials and mechanical engineering.